|

|

|

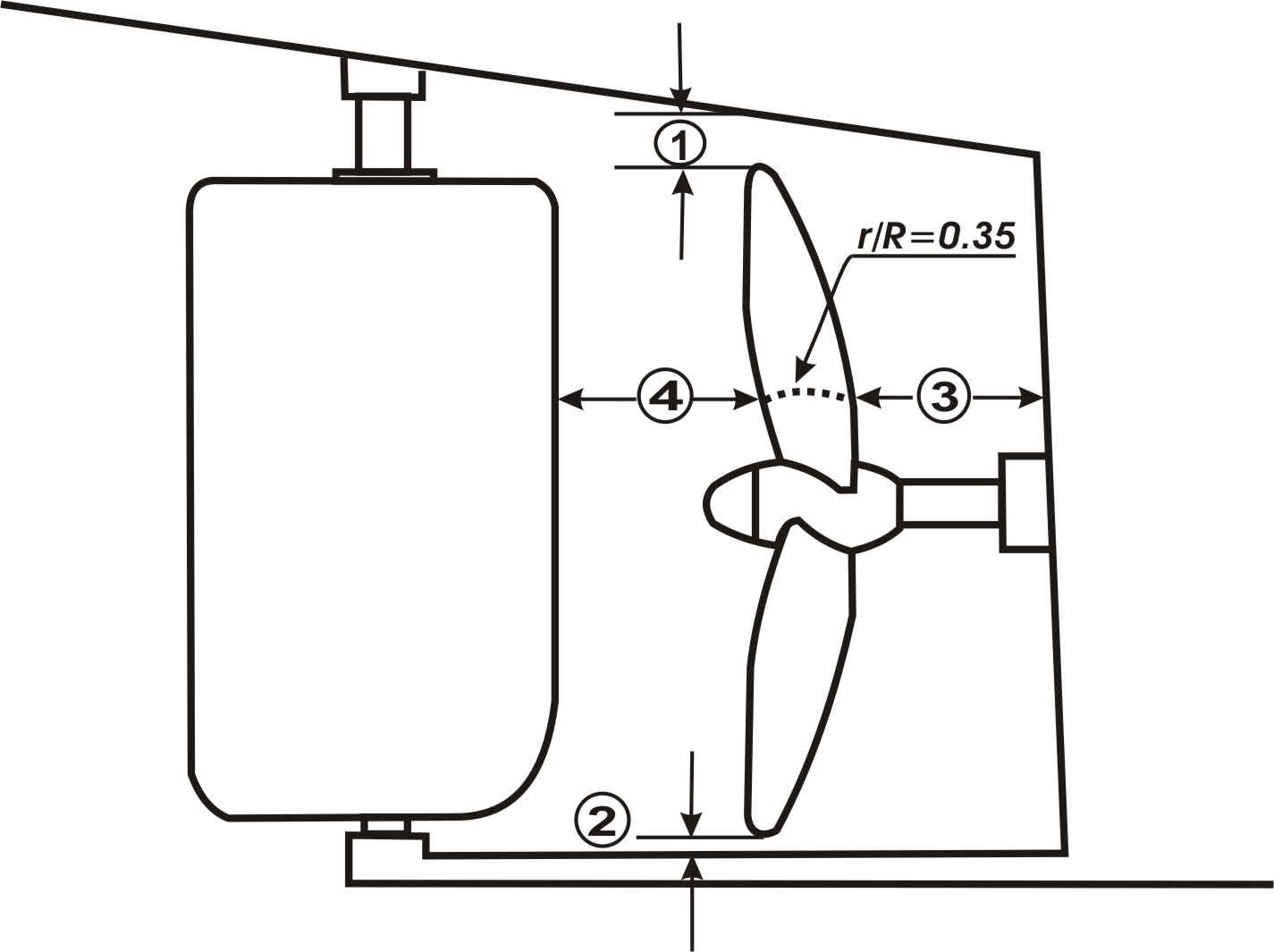

| CLEARANCES AND THE PROPELLER APERTURE | |

|

The

distances between the propeller and the hull affect how efficiently the

propeller operates within the flow of water around the hull, and the

amount of vibration caused by the propeller.

Table and figure show recommended clearances: |

From the desktop of |

Three-bladed propeller

Clearances

% of propeller diameter

1 Minimum clearance between tip and hull (1) 17% 2 Minimum clearance between tip and keel 4% 3 Minimum distance from deadwood to propeller(2) at 0.35 r/R of propeller blade diameter 27% 4 Maximum distance from propeller to rudder at 0.35 r/R of propeller blade diameter 10%

(NOTE) These clearances are closely associated with the number of blades and can be estimated by

(1) % = 0.23 - (0.02 x n) and (2) % = 0.33 - (0.02x n)

where: n = the number of blades on the propeller

In general, the larger the clearances the better.

However, if the aperture size is limited, larger clearances also imply a smaller propeller diameter, which is very detrimental to efficiency.During the design stage, the inclusion of large clearances have the effect of raising the counter and may force more obtuse waterlines just forward of the propeller.

Both of these increase the resistance of the hull in the water. A small aperture requires the installation of a small-diameter propeller, which may not be able to absorb all of the engine’s power efficiently, thus resulting in inefficient performance, engine damage or poor towing capacity.

An intermediate solution to a small aperture can be found, for example by:

The creation of a new shaft angle (this requires the remounting of the engine).

The use of a shaft extension (which often requires moving the rudder).

Or by the installation of a propeller with a higher blade area ratio.

IN GENERAL:

Tip clearances should be as small as possible within guidelines, in order to accommodate the largest possible propeller.

The distance from the propeller to the rudder should be kept small to maintain steering control.

The distance from the deadwood to the propeller should be large.

In the design and installation of trawler propellers, the tip-to-hull clearance can be as little as 8 to 10 percent of propeller diameter. The penalty of increased vibration being compensated for by the higher thrust and efficiency of a larger diameter propeller.

Reference:

FAO - Food and Agriculture Organization

of the United Nations

FAO FISHERIES TECHNICAL PAPER 383

|

If you have any suggestions or questions regarding these technical issues, or if you know someone who's willing to receive these technical letters, or if you wish to be removed from our mailing list, please send an e-mail to: technicalletter@ricepropulsion.com |